All News /

News:

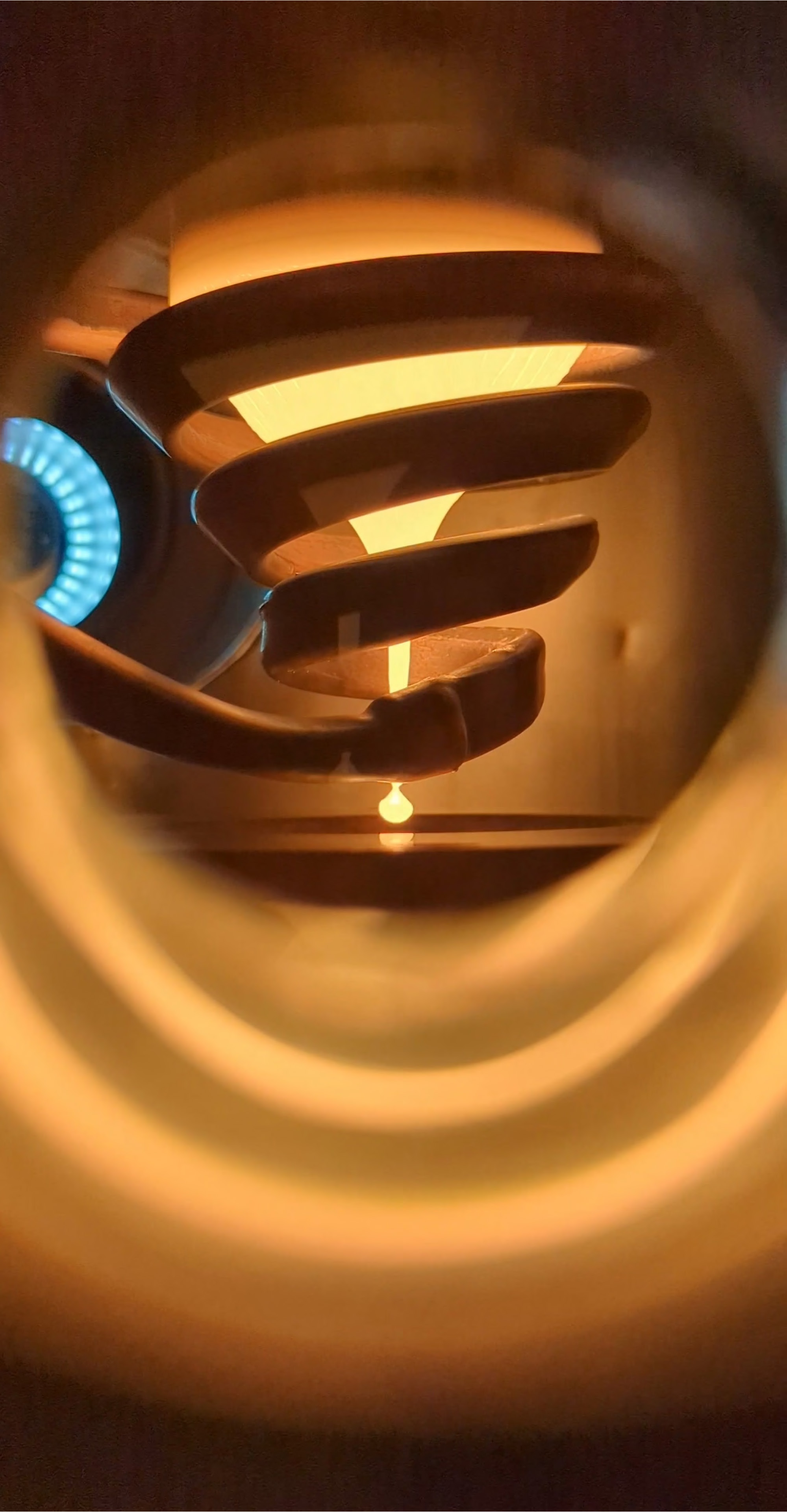

The BeAM Magic 2.0

19 / 10 / 17

MAPP is set to benefit from a new blown powder AM machine that will open up new research opportunities and meet a need highlighted by industry partners.

Blown powder AM is often used by the aerospace sector to repair gas turbine engine shaft seals, stator vanes, LPT Blades, and other high-value components.

The BeAM Magic 2.0 has been installed at Sheffield as part of the Henry Royce Institute. The machine’s capabilities include creating new alloys in-situ so the properties of the deposited material can be changed during the build process. Additional applications for the Magic 2.0 include combining multiple advanced technologies such as Powder Bed Fusion and Directed Energy Deposition.

MAPP Director Professor Iain Todd said: “The Magic 2.0 has a different set of capabilities to the other machines at the Sheffield MAPP site.

"It opens up a number of industrial research possibilities, in particular, the creation of new alloys in-situ and the chance to combine multiple advanced technologies, and we are looking forward to working with it.”

BeAM, a European manufacturer of industrial metal 3D printers/additive manufacturing machines using the LMD technology (Laser Metal Deposition), describe the Magic 2.0 as a “large format five continuous axis machine designed for serial production or repair of high-value components in industries with long lead times and high buy-to-fly ratios. The standard machine specifications include an X,Y,Z build volume of 1200 x 800 x 800, Siemens 840D Control, IPG 2KW Fiber Laser, MacroCLAD 10Vx Deposition Head along with many other industry-leading features.”

More:

News

-

-

Exploring STEM - 4th May 2023

The MAPP Stand was a hit at the Exploring STEM for Girls event at the Octagon on the 4 May 2023.<...