All Demonstrators /

Demonstrators:

Artifact Library

09 / 08 / 17

Pictured above: Part of the super lightweight, aerodynamic stem and handlebars made for Sir Bradley Wiggins.

Material: Titanium Alloy (Ti-6Al- 4V)

Process: Electron Beam Melting (EBM)

Material: Titanium Alloy (Ti-6Al- 4V)

Process: Electron Beam Melting (EBM)

Journal Paper: Ozdemir, Z., Hernandez-Nava, E., Tyas, A., Warren, J.A., Fay, S.D., Goodall, R., Todd, I. & Askes, H. (2016). Energy absorption in lattice structures in dynamics: Experiments. International Journal of Impact Engineering. 89, 49-61.

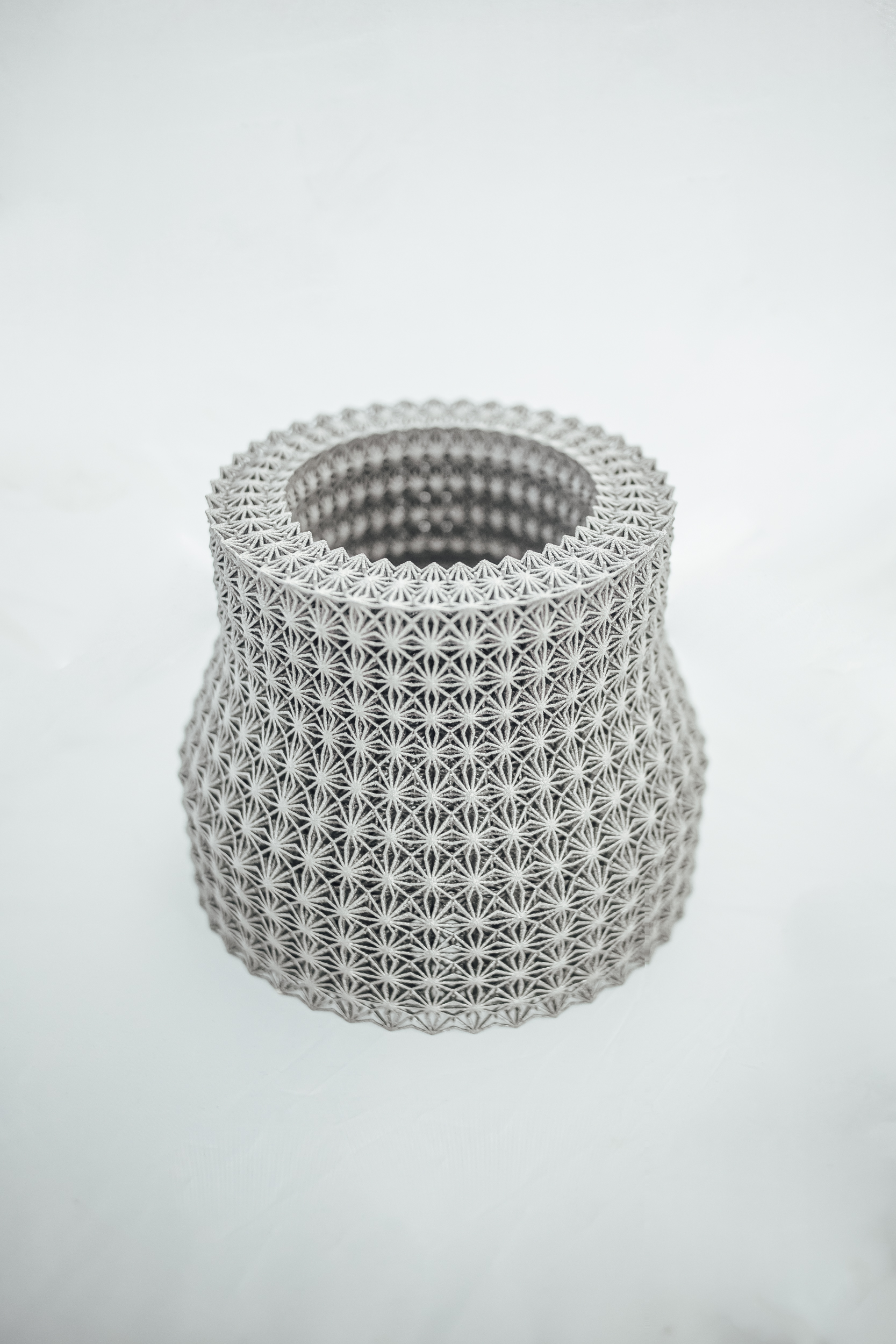

Material: Titanium Alloy (Ti-6Al- 4V)

Process: Electron Beam Melting (EBM)

Journal Paper: Smith, C.J., Gilbert, M., Todd, I., et al. (2016). Application of layout optimization to the design of additively manufactured metallic components. Structural and Multidisciplinary Optimization. 54, 1297-1313.

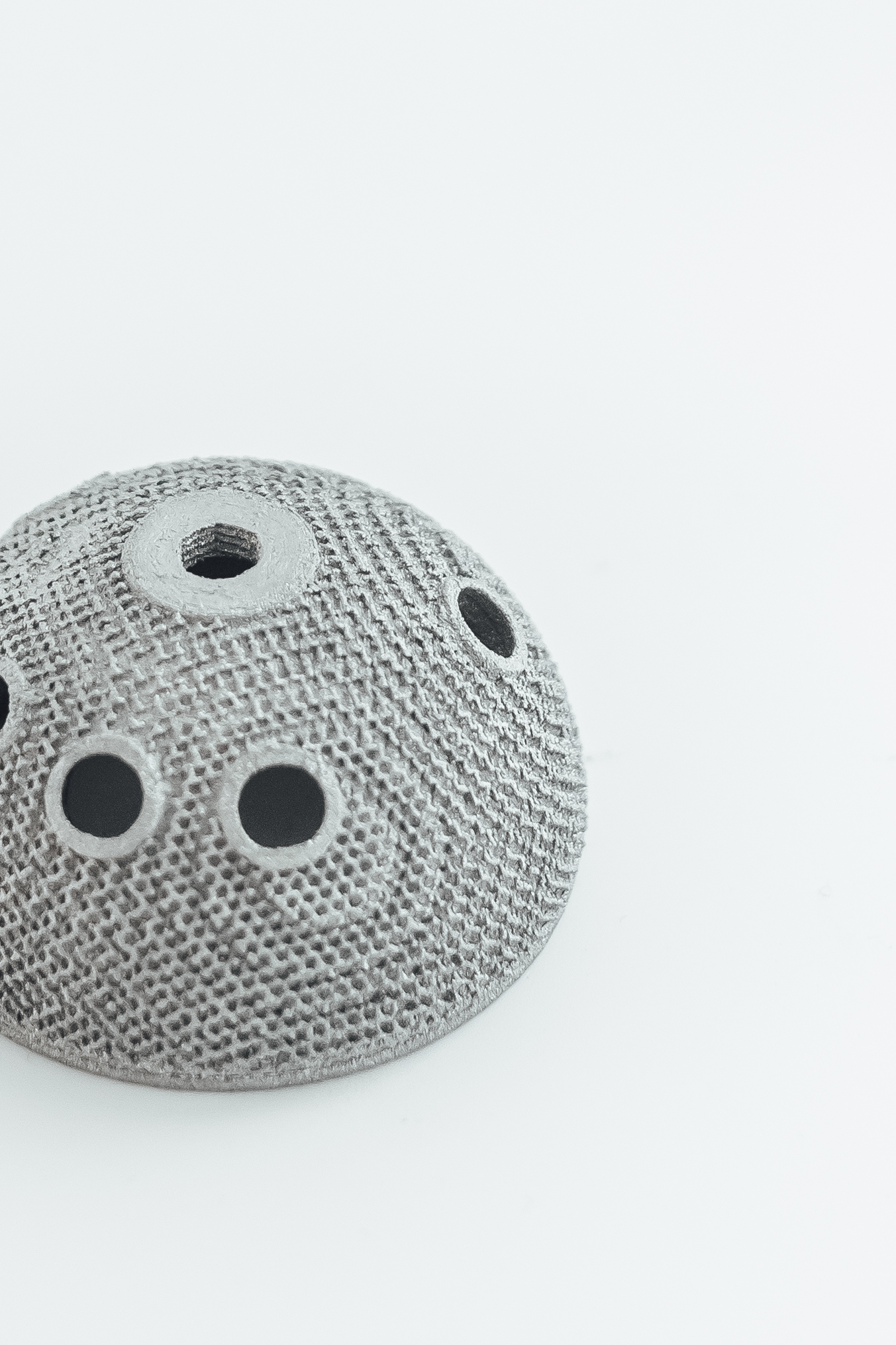

Material: Titanium Alloy (Ti-6Al- 4V)

Process: Electron Beam Melting (EBM)

Partners: The BLOODHOUND Project

Material: Titanium Alloy (Ti-6Al- 4V)

Process: Electron Beam Melting (EBM)

Journal Paper: Tammas-Williams, S. & Todd, I. (2017). Design for additive manufacturing with site-specific properties in metals and alloys. Scripta Materialia. 135,105-110.

Material: Titanium Alloy (Ti-6Al- 4V)

Process: Electron Beam Melting (EBM)

Journal Paper: Hernandez-Nava, E., Smith, C.J., Derguti, F., Tammas-Williams, S., Leonard, F., Withers, P.J., Todd, I. & Goodall, R. (2015). The effect of density and feature size on mechanical properties of isostructural metallic foams produced by additive manufacturing. Acta Materialia. 85, 387-395.