All Publications /

Publications:

Understanding the influence of porosity to help improve and predict fatigue life

04 / 08 / 17

Paper: The Influence of Porosity on Fatigue Crack Initiation in Additively Manufactured (AM) Titanium Components

Publication: Scientific Reports, 7, 7308 (2017)

Authors: Sam Tammas-Williams, Philip Withers, Iain Todd and Philip Prangnell.

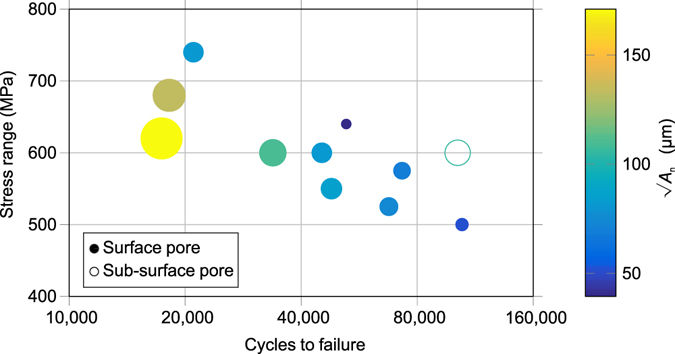

Fatigue life relates to how long components will last before failing due to weakening caused by repeated loading. There are a number of different factors that can influence fatigue life including the type of material, its microstructure, its shape, loading conditions and temperature. Understanding and improving the fatigue performance of components made by new manufacturing methods is essential for safety critical components used in aerospace. This paper sheds new light on the fatigue properties of materials manufactured using electron beam melting (EBM) and possible strategies for improving fatigue performance.

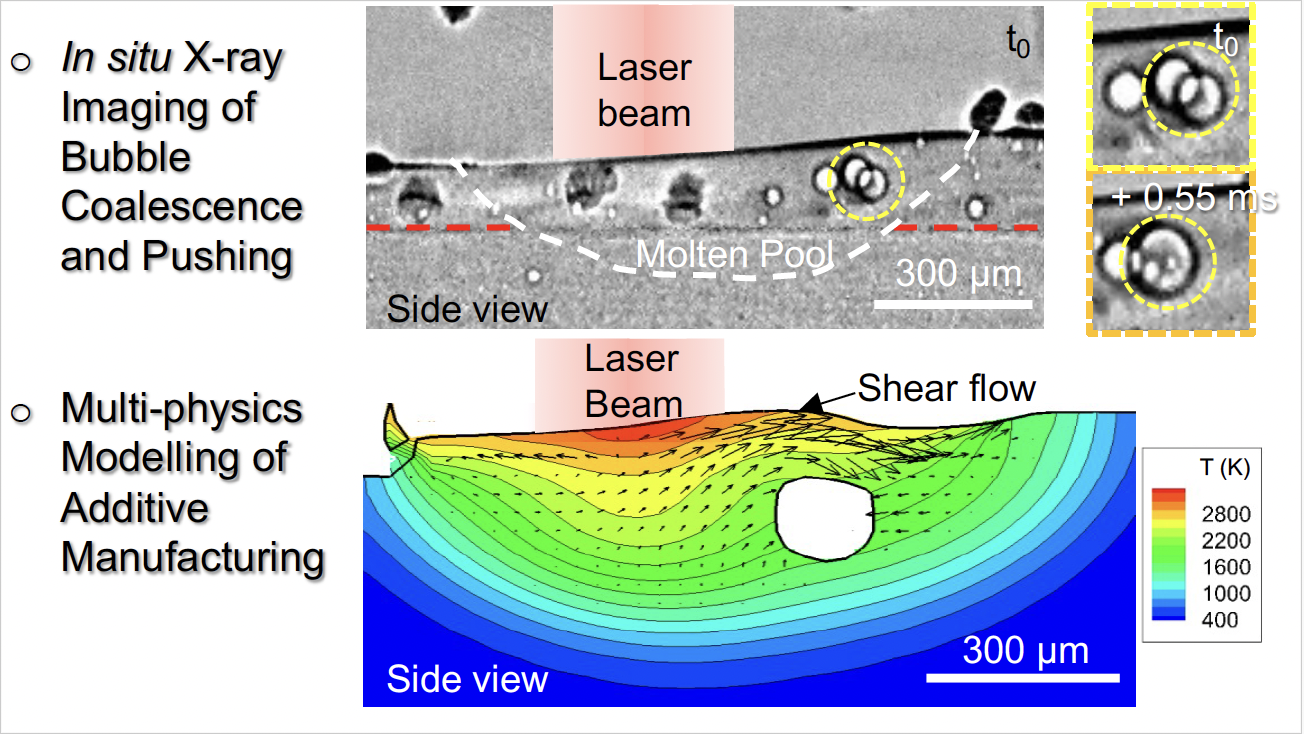

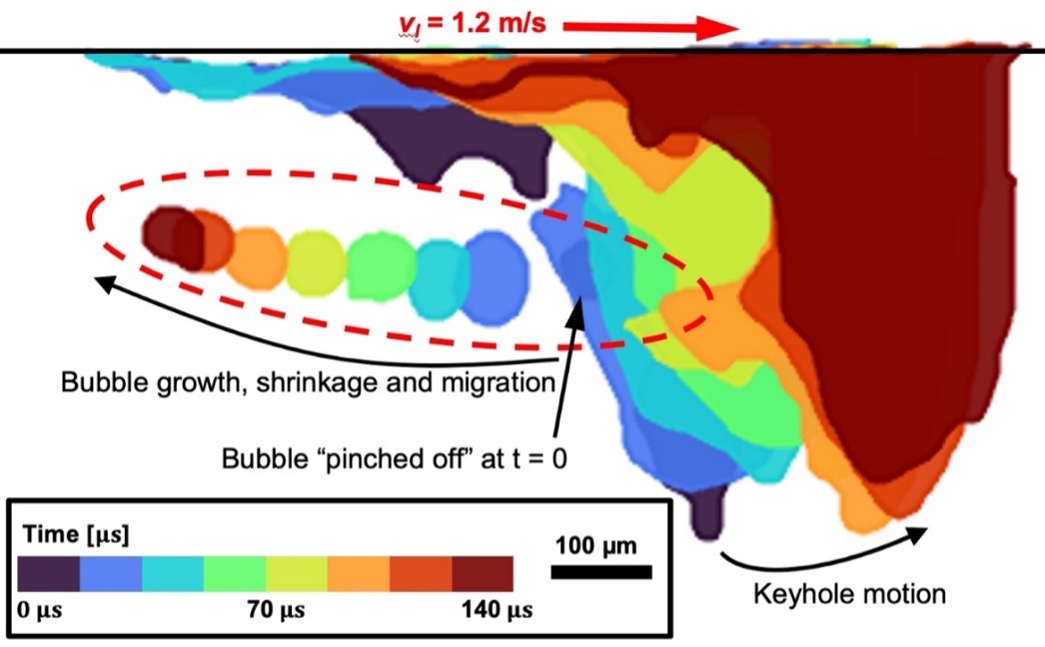

The paper demonstrates the use of a new time-lapse x-ray computed tomography (CT) method to improve the understanding of the effect of pores on the fatigue life of components made using EBM by tracking fatigue crack initiation and growth in 3D.

It confirms that the fatigue lives of samples manufactured by EBM are strongly influenced by the presence of retained porosity, with fatigue life proportional to pore size.

A ranking technique is developed to predict which pores are the most detrimental to fatigue life. The analysis shows fatigue life improvement may be achieved by minor adjustment to the manufacturing process to avoid defects appearing in critical locations.

The paper can be viewed here.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...