All Publications /

Publications:

X1 Case Study B (UCL)

26 / 02 / 24

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu Lun Alex Leung

Collaborators: UKRI Research Complex at Harwell, UKRI STFC, Central Laser Facilities, Diamond Light Source Ltd., Henry Royce Institute, Cardiff University, HarwellXPS, TWI Ltd., National Structural Integrity Research Centre (NSIRC), European Space Agency, Imperial College London ,Conventry University, University of Leicester

One of the key factors that makes powder-based additive manufacturing process sustainable is the ability to reuse or/and recycle powder as often as possible. There are a number of questions raised in the additive manufacturing sector:

1. What are the effects of powder oxidation on the process and build quality?

2. Do the powder oxidation effects universaily apply on all powder feedstocks?

3. What are the chemical constiutents on the surface of oxidise powders?

Through MAPP, UCL MSM@H group led a series of collaborative research activities with several industrial and academic partners to tackle these questions. We mainly focused on the powder oxidation effect on Fe- [1] and Ti-based alloys [2, 3] by seeing the additive manufacturing processes as they build with both virgin and oxidised feedstock. Here, we will highlight what we have learnt so far with the application of X-ray imaging of both LPBF and DED processes.

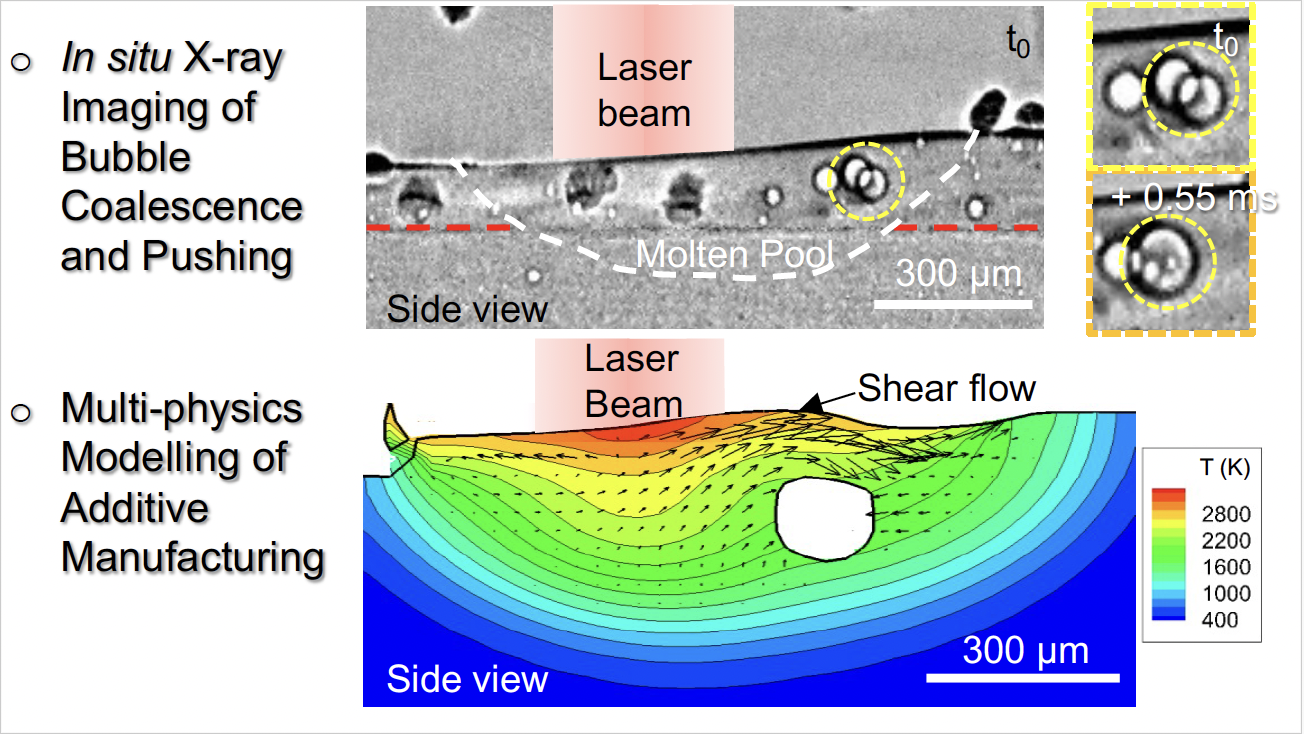

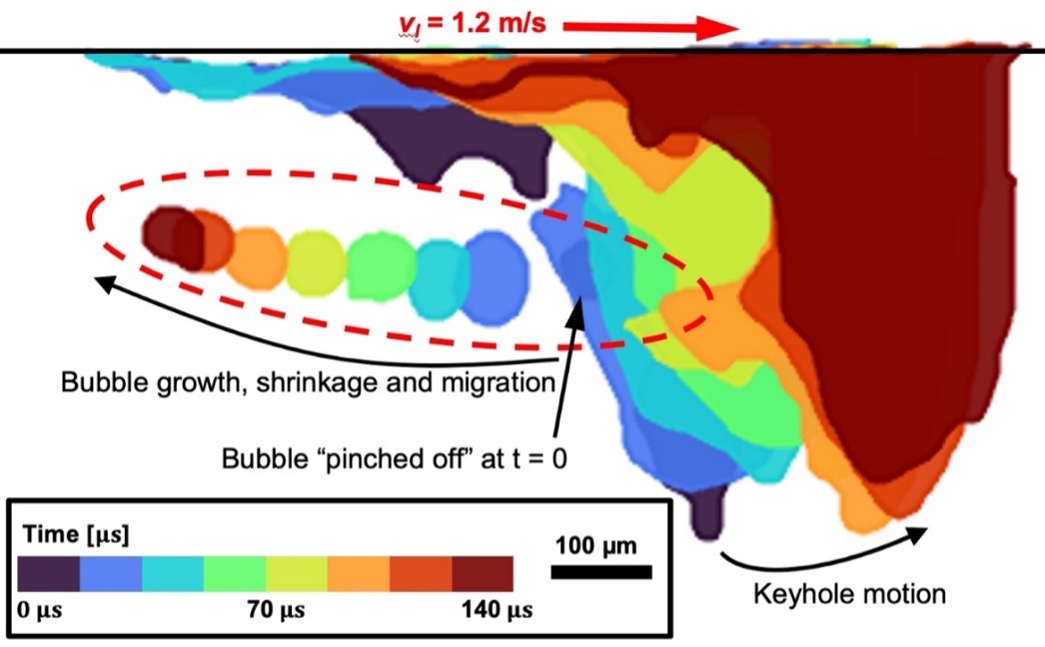

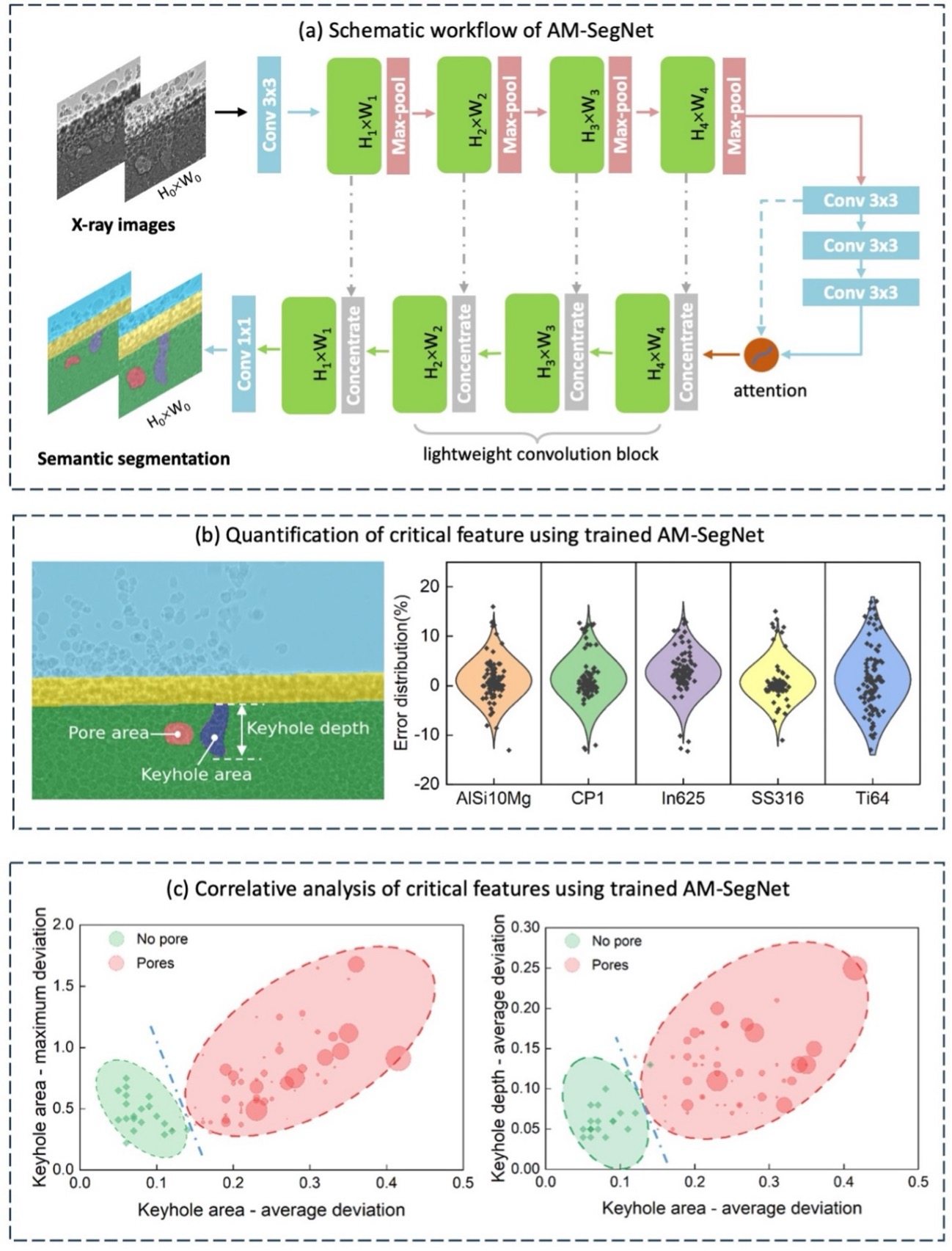

Leung et al. [1] investigated and explained the effects of powder oxidation during LPBF of virgin and oxdisied Invar36 (Fe-Ni) alloy feedstock using X-ray imaging. Using the collected X-ray images, we revealed and quantified molten pool dynamics and defect formation during LPBF under multilayer conditions. We used X-ray photoelectron spectroscopy (XPS) to quantify different types of oxides and carbon species presence at the surface of the powder feestock. Combined the XPS and X-ray imaging results, we hypothesised that iron and nickel oxides altered the Marangoni convection from an inward centrifugal to an outward centripetal flow. Our results also found that LPBF of oxidised Fe-Ni powder feestock promoted pore nucleation, stabilisation, growth, and bursting mechanisms, in which pore bursting lead to spatter formation. This study highlighted several detrimental effects of powder oxidation during LPBF.

Unlike our previous work [1], Soundarapandiyan et al.[2] studied LPBF of oxdised Ti6Al4V powder (0.4 wt% oxygen) using X-ray imaging and found that oxidised powder can reduce melt pool instabilities and surface roughness. Stable melt pool also led to less formation of droplet spatter and porosity during LPBF, enchancing the printability. With the aid of UV-VIS-NIR spectroscopy, we found that the oxide species lower the absorptivity (,i.e. optical property) of powder feedstock in the near-infrared spectrum by half. We hypothesis that the melt pool is at a lower temperature than that from the virgin build under the same processing conditions. As a result of that, this increases the viscosity of the melt whilst making the melt flow behaviour less vigorous, leading to fewer defects found in LPBF. This work highlights the role of oxygen on melt pool and defect dynamics during LPBF is alloy dependent.

Similar to refs [1, 2], Iantaffi et al. [3] also reported the presence of oxygen during directed energy deposition (DED) of Ti6242 reversed the Marangoni flow, i.e. such reversal mechanism deem to be universality applied in Fe- and Ti- alloys, matching well with the welding literature [4]. Similar to ref [2], oxygen reduces porosity formation, however, it promotes crack formation during DED of Ti6242. In summary, the effects of powder oxidation on defect dynamics remain unclear from our intitial studies. It remains crucial to determine the critical level of oxygen level that lead to unacceptable processing conditions.

From our first series of in situ studies, UCL is now collaborating with Carpenter Additive, a world-leading powder producer to co-fund a student who will tacke the remaining questions during AM of three common alloy systems for aerospace applications. It is a priviledge to see our work is being recongised by industry and how X-ray imaging can continue to help improve our fundamental understanding of AM process.

References:

1. https://www.sciencedirect.com/science/article/abs/pii/S1359645418309698

2. https://www.sciencedirect.com/science/article/pii/S0890695523000573

3. https://www.sciencedirect.com/science/article/pii/S2772369021000220

4. https://royalsocietypublishing.org/doi/abs/10.1098/rsta.1998.0196

Publications:

• https://www.sciencedirect.com/science/article/abs/pii/S1359645418309698

• https://www.sciencedirect.com/science/article/pii/S0890695523000573

• https://www.sciencedirect.com/science/article/pii/S2772369021000220