All Publications /

Publications:

P2.3 Case Study A (Imperial)

26 / 02 / 24

Graphene-Enhanced Powder Feedstocks for Laser Assisted Manufacturing

Investigators: Prof. Eduardo Saiz (Imperial)

Researchers: Dr I Elizarova (Imperial)

Collaborators: IC/UCL/Sheffield/Graphene First

Direct Laser Additive Manufacturing (DLAM) is a very versatile technology that opens new opportunities in component design and fabrication. Its success relies on the engineering of the right powder feedstocks. Currently, DLAM is used with a very limited in a range of materials due to variations in laser absorption among compounds. Most are simply laser reflective or transparent and do not absorb enough laser energy to enable desification. In some cases it may be possible to work around this problem by using specialized laser set-ups. However, it will be advantageous and efficient to use a single universal printing system with the widest possible range of materials.

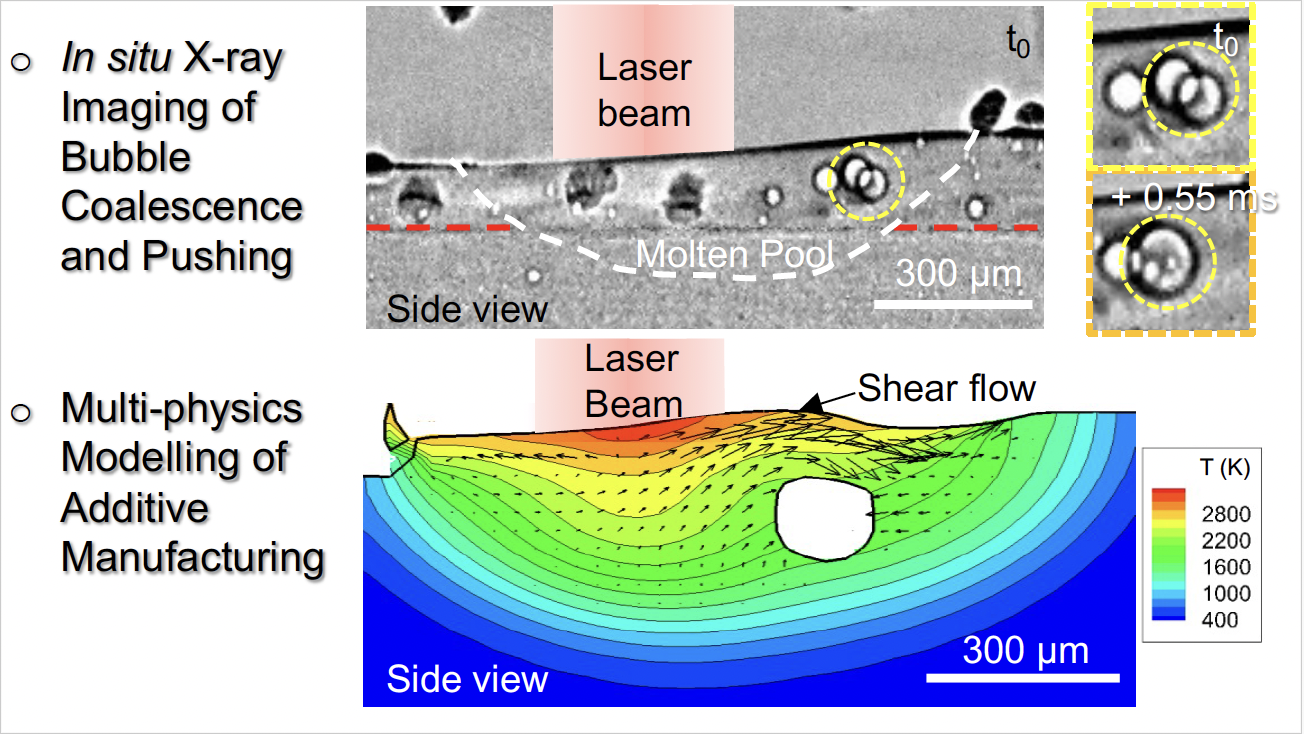

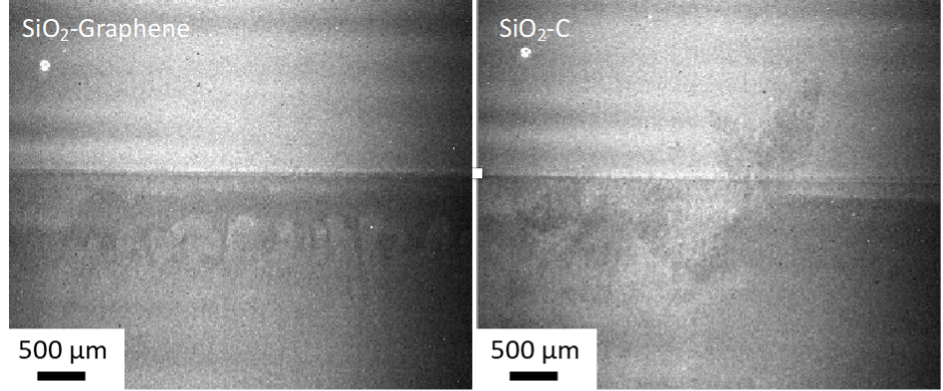

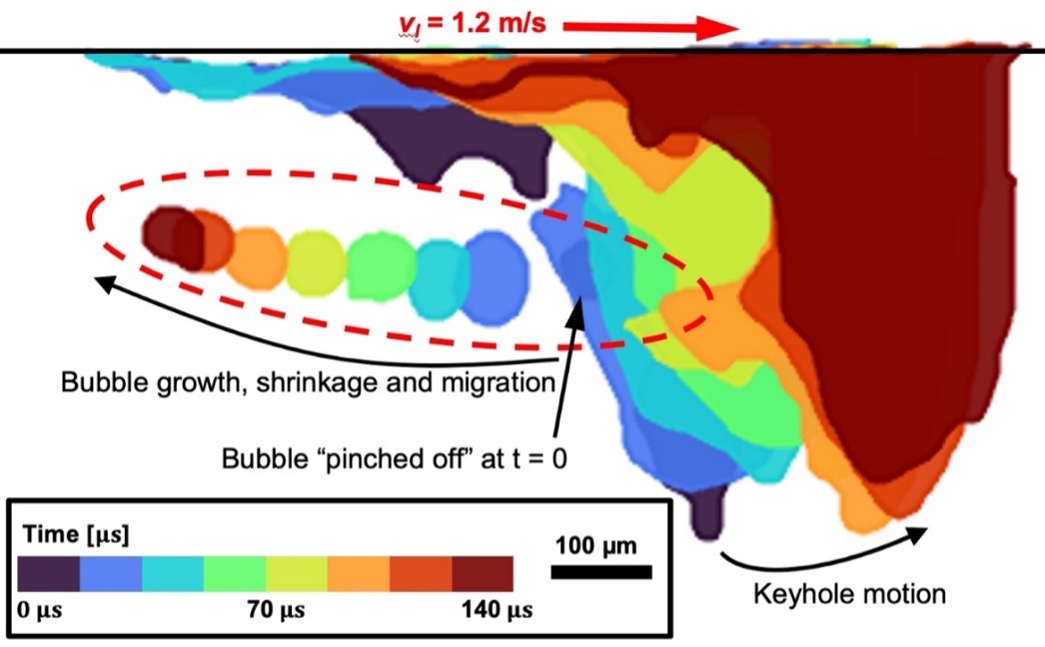

Within the framework of MAPP and in collaboration with UCL and the University of Sheffied we have been working on the development of powder feedstocks containing chemically modified graphene (CMG) as a processing additive to promote laser adsorption. The work brings together a team with experience in ceramics and metal processing. It combines the engineering of graphene and graphene-enhanced powder feedstocks with in operando high-speed xRay imaging and in depth characterization of the printed parts. The goal is to develop a fundamental understanding of the relationship between graphene chemistry and flake size, feedstock characteristics and printing performance. Initial results have shown that CMG is much more efficient that conventional carbon black additives and very small additions (0.2wt%) enable laser bed powder fusion of silica glass with an standard near infrared laser. Currently we are extending our work towards the development of different metallic (e.g., copper) or ceramic (alumina or zirconia) feedstocks. The results have supported a pattend application and attracted additional Impact Acceleration funds to back the development of the technology in collaboration with Graphene First.

The development of new feedstocks can unleash the potential of the technology. The use of graphene as an additive can open the palete of materials that could be used in DLAM, increasing efficiency and resolution reducing while reducing emissions and materials waste. It will enable the fabrication of new, more efficient components with enhanced properties for a wide range of technologies, from transportation to energy generation and storage. In addition, it may open opportunities in the reciclyng of powders that are currently difficult to process.

Further Information:

1. UKRI Impact Acceleration Funding, Graphene-enabled universal laser additive manufacturing, £79K.

2. Enhanced feedstock for additive manufacturing, CLA Leung, I Elizarova, PD Lee, E Saiz, US Patent App. 18/249,495

Paper/Publication DOI:

1. Enhanced near-infrared absorption for laser powder bed fusion using reduced graphene oxide, CLA Leung, I Elizarova, M Isaacs, S Marathe, E Saiz, PD Lee, Applied Materials Today 23, 101009SME. https://doi.org/10.1016/j.apmt.2021.101009

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...