All Publications /

Publications:

New publications in February and March 2021

31 / 03 / 21

MAPP journal papers published in February and March include those listed below:

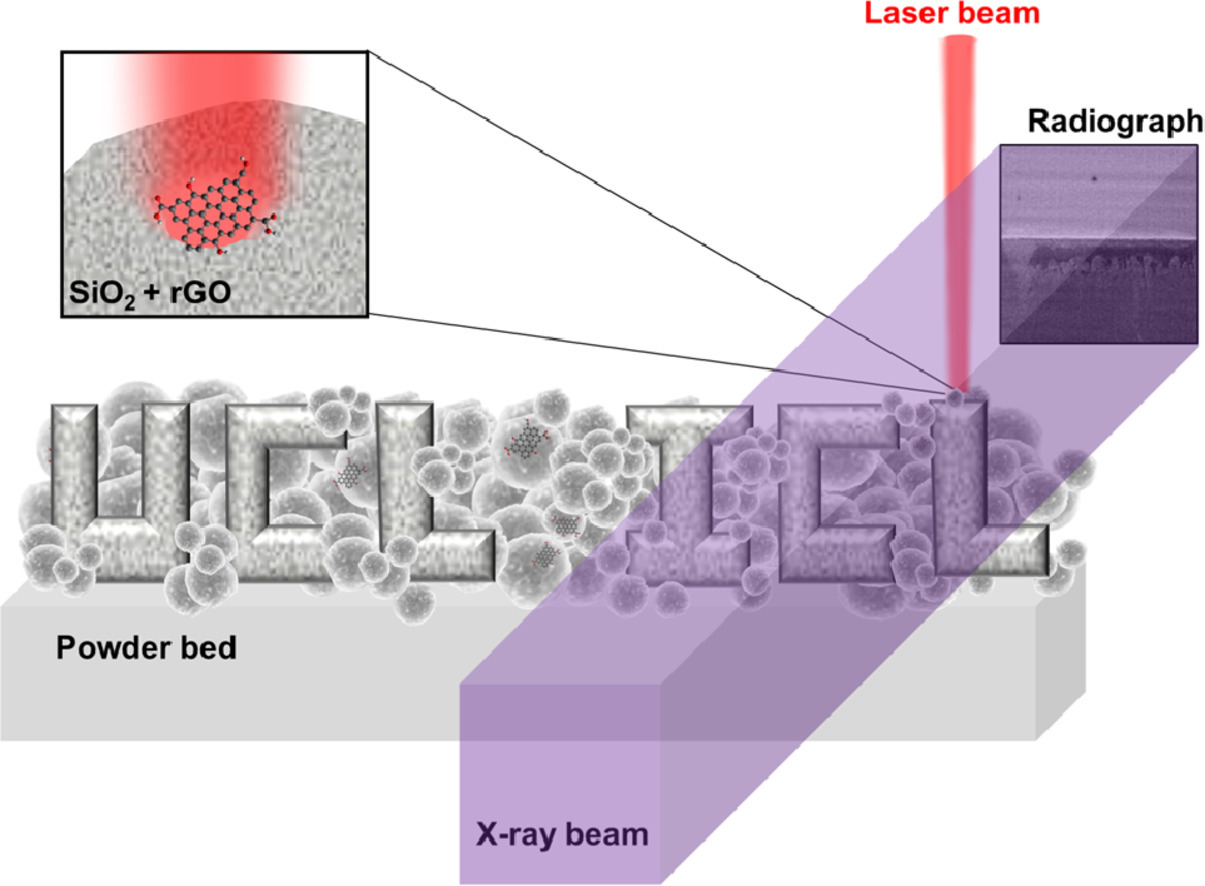

Enhanced near-infrared absorption for laser powder bed fusion using reduced graphene oxide

Chu Lun Alex Leung, C.L.A., Elizarova, I., Isaacs, M., Marathe, S., Saiz, E., Lee, P.D., (2021) Enhanced near-infrared absorption for laser powder bed fusion using reduced graphene oxide. Applied Materials Today, 23, 101009.

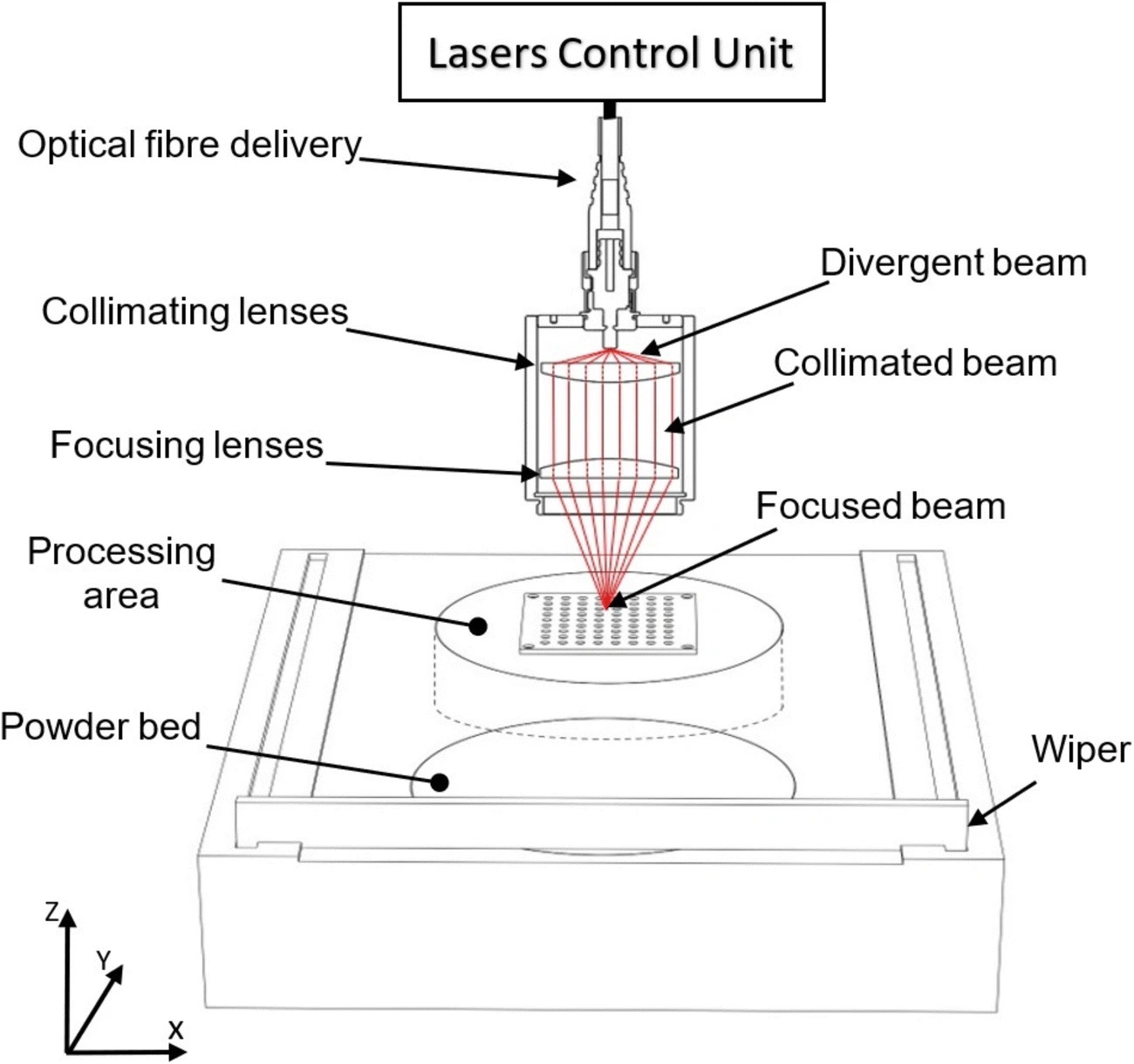

Use of 450-808 nm diode lasers for efficient energy absorption during powder bed fusion of Ti6Al4V

Alsaddah, M., Khan, A., Groom, K. et. al., (2021) Use of 450-808 nm diode lasers for efficient energy absorption during powder bed fusion of Ti6Al4V. Int J Adv Manuf Technol 113, 2461–2480.

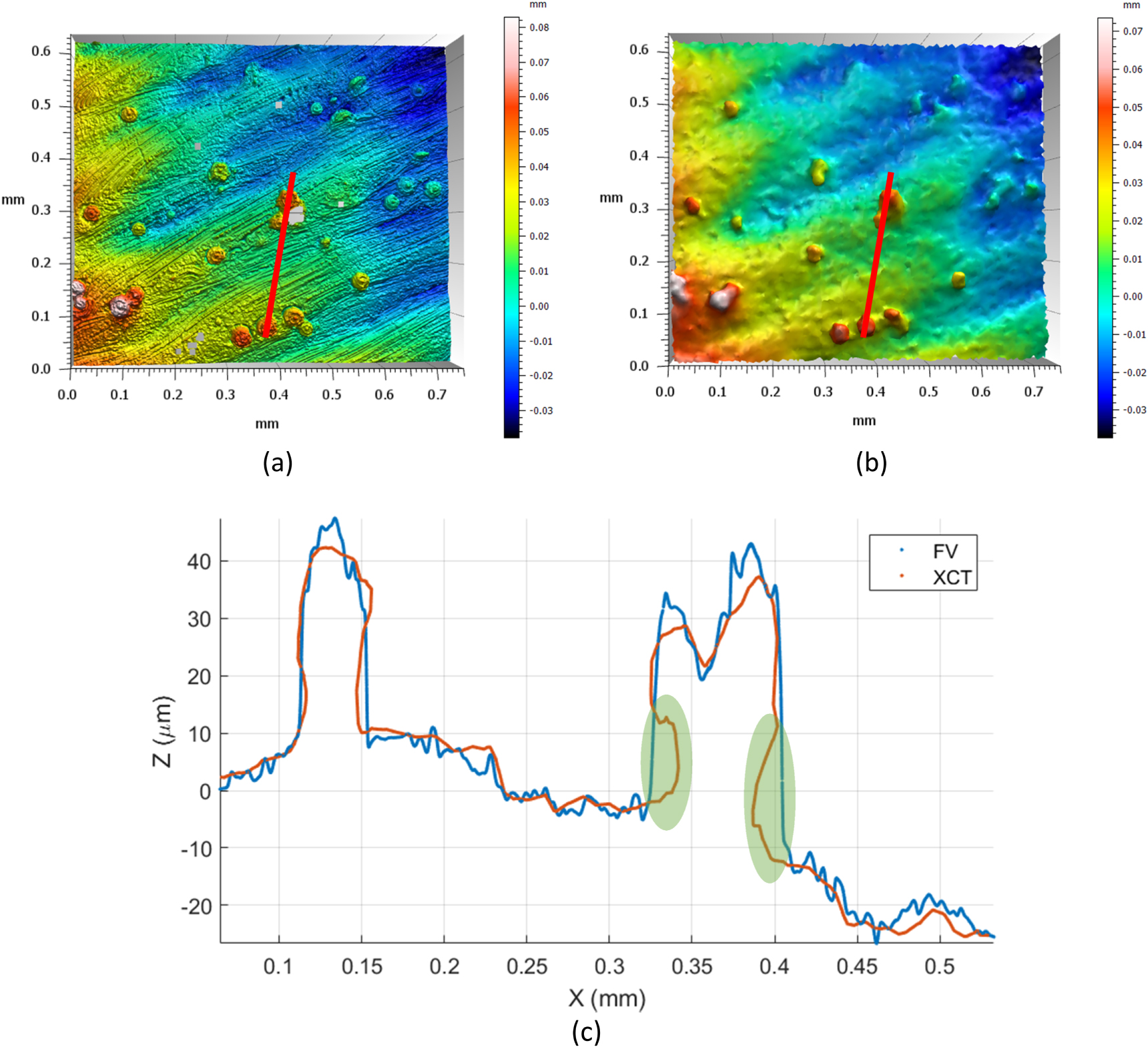

Material ratio curve of 3D surface topography of additively manufactured parts: an attempt to characterise open surface pores

Lou, S., Zhu, Z., Zeng, W., Majewski, C., Scott, P.J., Jiang, X., (2021) Material ratio curve of 3D surface topography of additively manufactured parts: an attempt to characterise open surface pores. Surf. Topogr. Metrol. Prop. 9, 015029.

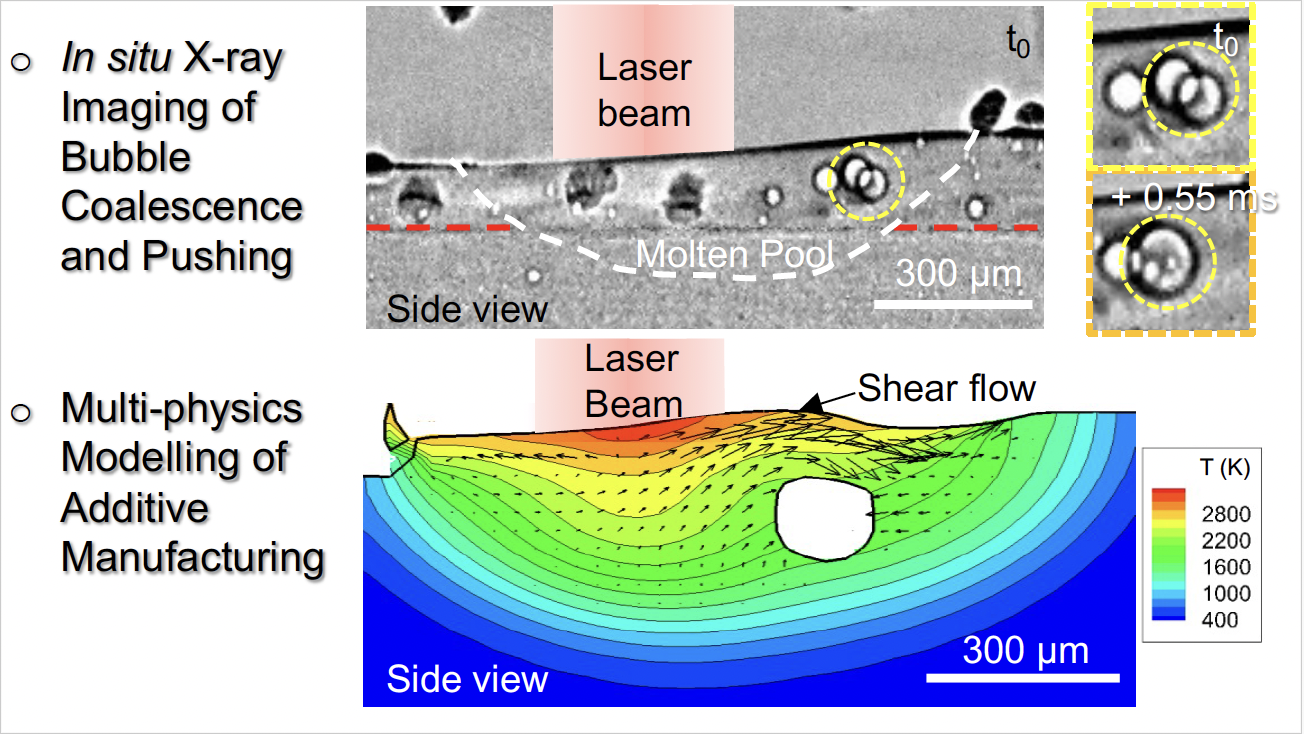

Correlative Synchrotron X-ray Imaging and Diffraction of Directed Energy Deposition Additive Manufacturing

Chen, Y.H., Clark, S.J., Collins, D.M., Marussi, S., Hunt, S.A., Fenech, D.M., Connolley, T., Atwood, R.C., Magdysyuk, O.V., Baxter, G.J., Jones, M.A., Leung, C.L.A., Lee, P.D., (2021) Correlative Synchrotron X-ray Imaging and Diffraction of Directed Energy Deposition Additive Manufacturing, Acta Materialia, 209 116777.

Synchrotron X-ray Imaging of Directed Energy Deposition Additive Manufacturing of Titanium Alloy Ti-6242

Chen, Y.H., Clark, S.J., Sinclair, L., Leung, C.L.A., Marussi, S., Connolley, T., Atwood, R.C., Baxter, G.J., Jones, M.A., Todd, I., Lee, P.D., (2021) Synchrotron X-ray Imaging of Directed Energy Deposition Additive Manufacturing of Titanium Alloy Ti-6242, Additive Manufacturing, 41, 101969.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...