All Publications /

Publications:

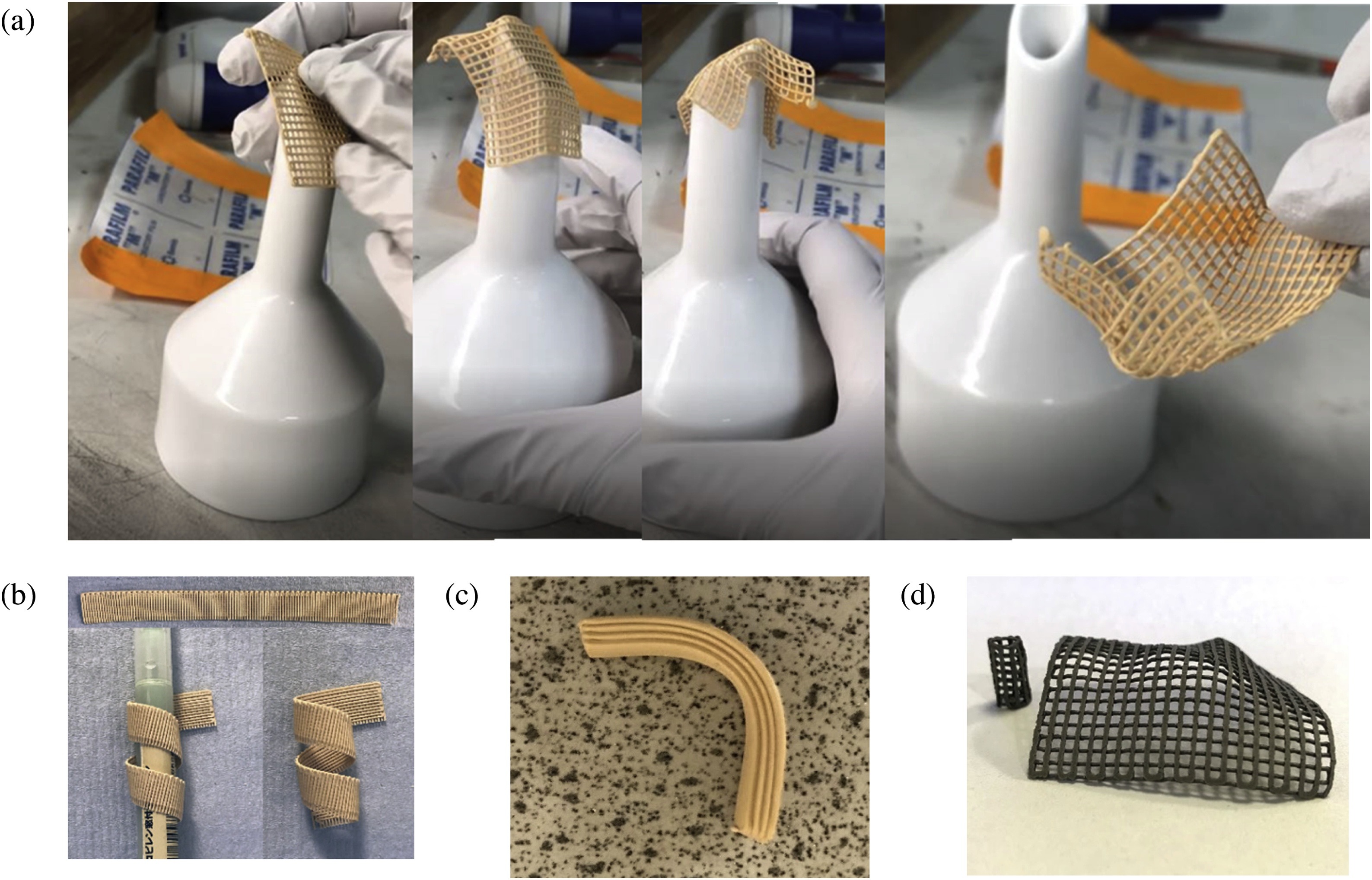

Conformable green bodies: Plastic forming of robocasted advanced ceramics

25 / 08 / 20

MAPP members at the Centre for Advanced Structural Ceramics have developed a new phenolic resin-based paste for robocasting of ceramic powders that allows post-printing shaping.

The development is discussed in the paper Conformable green bodies: Plastic forming of robocasted advanced ceramics, published in the Journal of the European Ceramic Society.

Robocasting is an additive manufacturing technology based on the continuous extrusion of a ceramic paste. It has limited capabilities when printing complex unsupported structures such as overhangs.

The new type of paste addresses this limitation by allowing the shaping of the ceramic body, known as green bodies, before sintering (a heat treatment applied to impart strength and integrity).

The paste consists of a solution of phenolic resin in methyl ethyl ketone and ceramic powders. The phenolic resin in the paste acts as a binder and plasticizer and can be burned out during sintering, or, additionally, can be converted into carbon that can later act as a sintering aid.

After printing parts can be cut, bent, folded and draped over various objects. Once dry and fully solid, the parts become rigid and can be processed further by slow pyrolysis (slow heating in absence of oxygen) and sintering.

The shaping of the green bodies after printing does not affect the mechanical strength of the sintered parts. The paste was used to produce both alumina and silicon carbide parts, illustrating its flexibility.

The new paste also addresses the difficulty of processing ceramics into arbitrary shapes, allowing more applications to benefit from the advantages of ceramic materials including strength and hardness.

The Centre for Advanced Structural Ceramics is a world-leading centre for ceramics research and teaching at Imperial College London.

Image: Reprinted from Journal of the European Ceramic Society, 40, (2), Elizarova, I., Vandeperre, L., Saiz, E., Conformable green bodies: Plastic forming of robocasted advanced ceramics, 552-557., Copyright (2020) with permission from Elsevier.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...