All Publications /

Publications:

Multi-faceted monitoring of powder flow rate variability in directed energy deposition

05 / 04 / 22

PAPER: Multi-faceted monitoring of powder flow rate variability in directed energy deposition

PUBLICATION: Additive Manufacturing Letters

AUTHORS: Freeman, F.S.H.B., Thomas, B., Chechik, L., Todd, I.

This paper deepens the understanding of powder flow rate, which is a key parameter in Directed Energy Deposition (DED) processes.

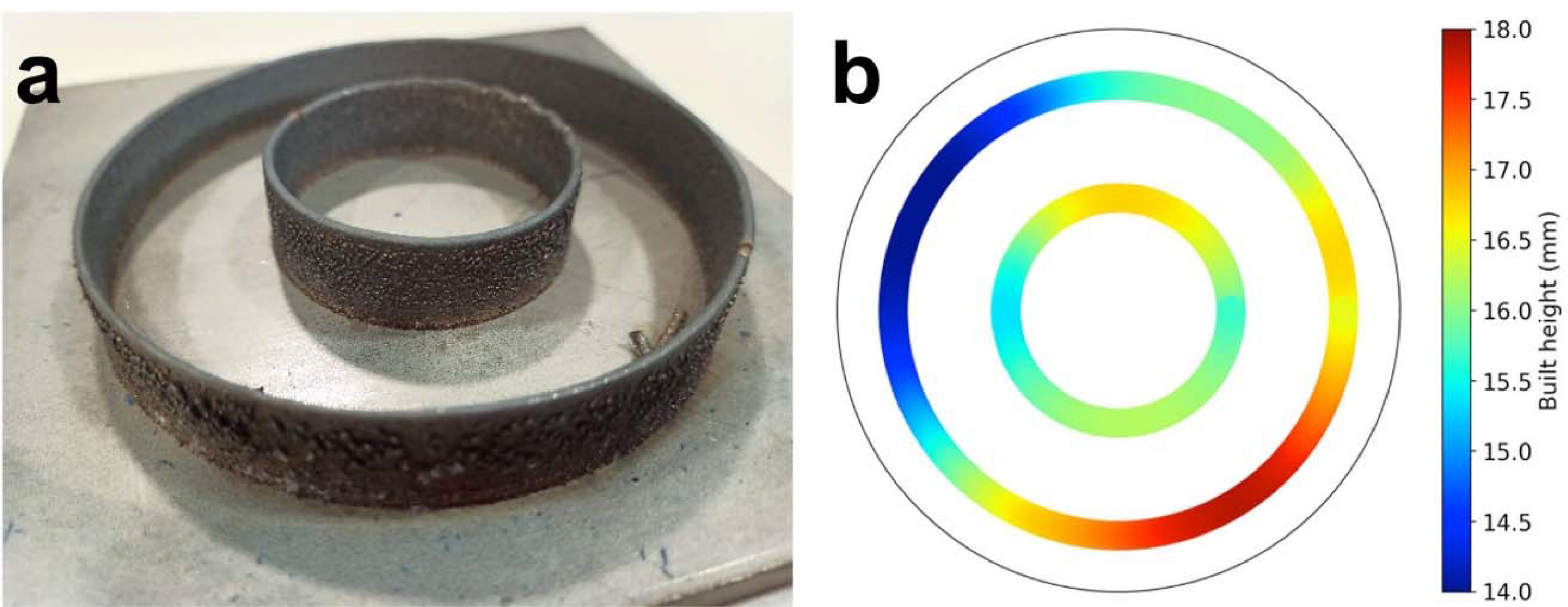

DED systems use nozzles to focus a mixed stream of metal powder and gas onto a substrate simultaneously with a laser directed onto the substrate which melts the powder to form a build. As the laser moves back and forth the deposit is built up in 3-D. The team have measured a periodic fluctuation in the powder delivery rate which is coincidental with the time of rotation of a disc used to deliver the powder from the hopper.

This work “confirmed that DED systems can experience variations in powder flow rate at a magnitude that can affect build quality and that this effect is observable in melt pool imaging.”

It highlights the need for closed-loop control of powder flow rate. This would “eliminate the need for offline measurement before a build, minimise the risk to build quality from flow rate variation, mitigate against fill level effects as the hopper gradually empties, and ensure that melt pool imaging for temperature monitoring was unaffected by flow rate effects.”

As a result of this investigation, the team is now working to determine whether process parameters can be altered dynamically to counteract the variation in powder flow rate which will enable this approach to be used on multiple different deposition platforms and with different hopper designs.

The DED machine used in this work was a BeAM Magic 2.0. The authors quantified the powder flow stability for different types of 316 L steel powders. A combination of methodologies including offline weight measurements, flow imaging, in-situ build data and coaxial melt pool imaging were used.

Click here to view the paper.

Images and quotes from Freeman, F.S.H.B. et al. Multi-faceted monitoring of powder flow rate variability in directed energy deposition. Additive Manufacturing Letters 2, 100024 (2022).

Used under Creative Commons license Attribution 4.0 International (CC BY 4.0).

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...