All Publications /

Publications:

Laser-matter interactions in additive manufacturing of stainless steel SS316L and 13-93 bioactive glass revealed by in situ X-ray imaging

17 / 01 / 19

Paper: Laser-matter interactions in additive manufacturing of stainless steel SS316L and 13-93 bioactive glass revealed by in situ X-ray imaging

Publication: Additive Manufacturing

Authors: Leung, C.L.A., Marussi, S., Towrie, M., Val Garcia, J., Atwood, R.C., Bodey, A.J., Jones, J.R., Withers, P.J., Lee, P.D.

MAPP researchers are using the UK’s national synchrotron, the Diamond Light Source, to shed more light on laser additive manufacturing (LAM) technologies.

Previously the in-situ real-time measurements used to learn more about LAM, including Schlieren imaging, have captured the temperature field and/or images at above the molten pool surface. But they cannot study the changes inside the melt zone.

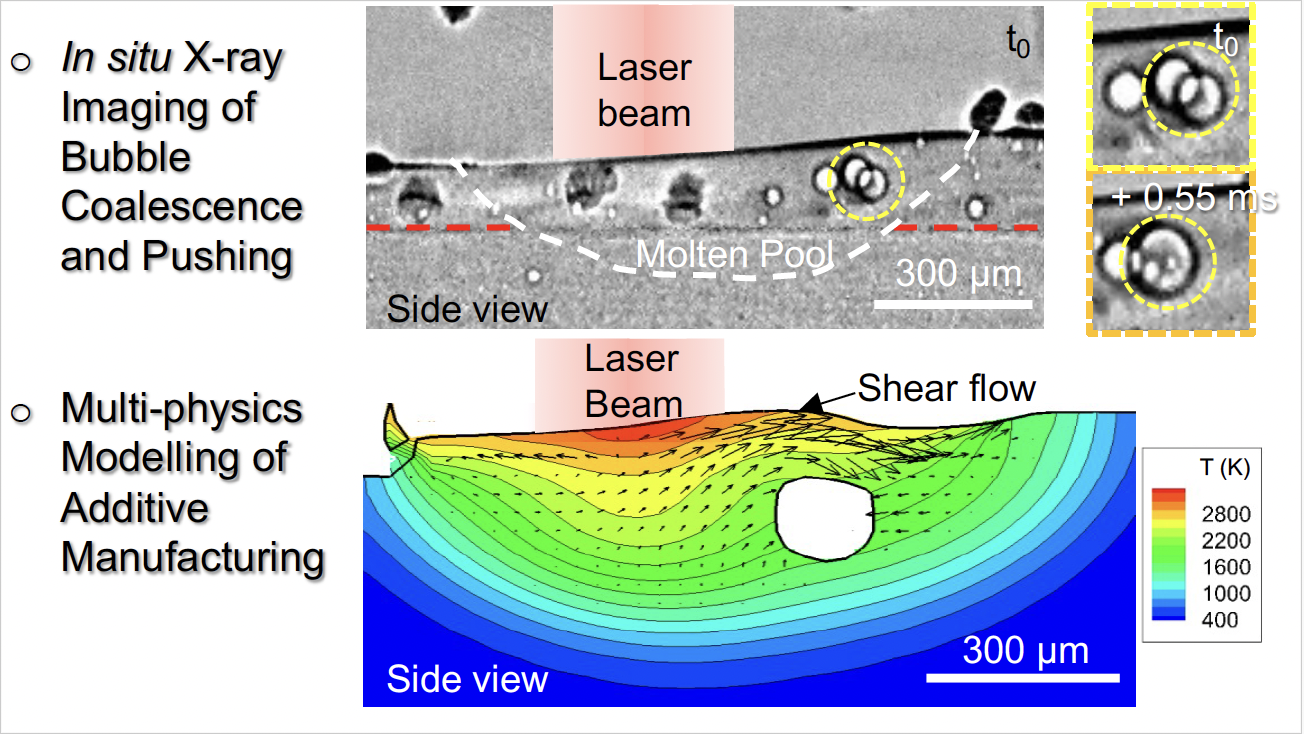

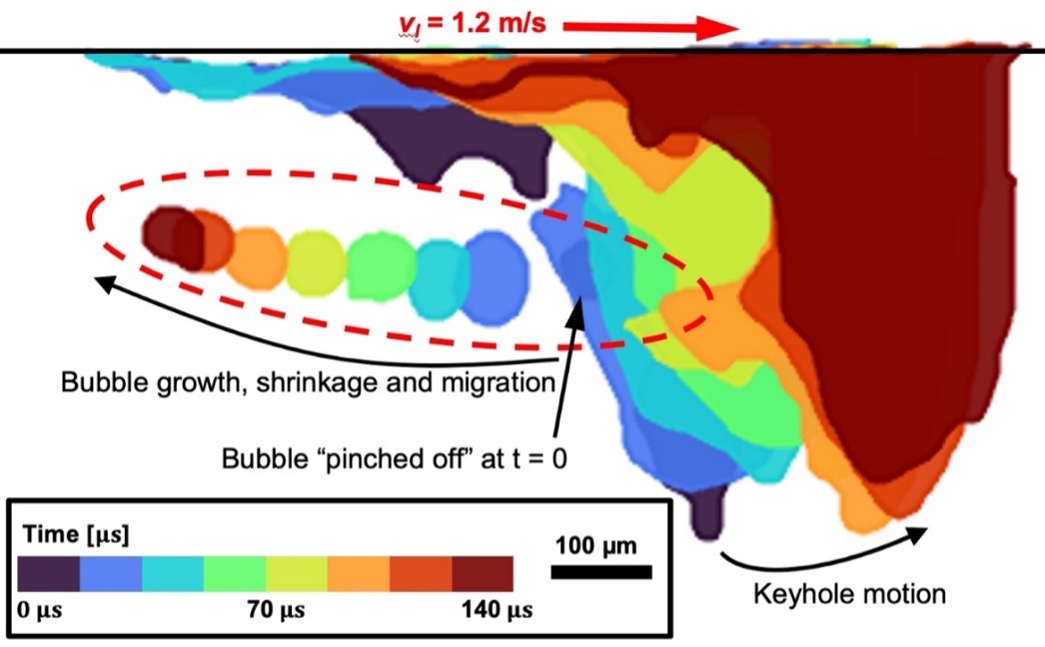

Advances in third-generation synchrotron radiation sources allow the use of a high flux X-ray beam to capture LAM radiographically at a high spatial and temporal resolution.

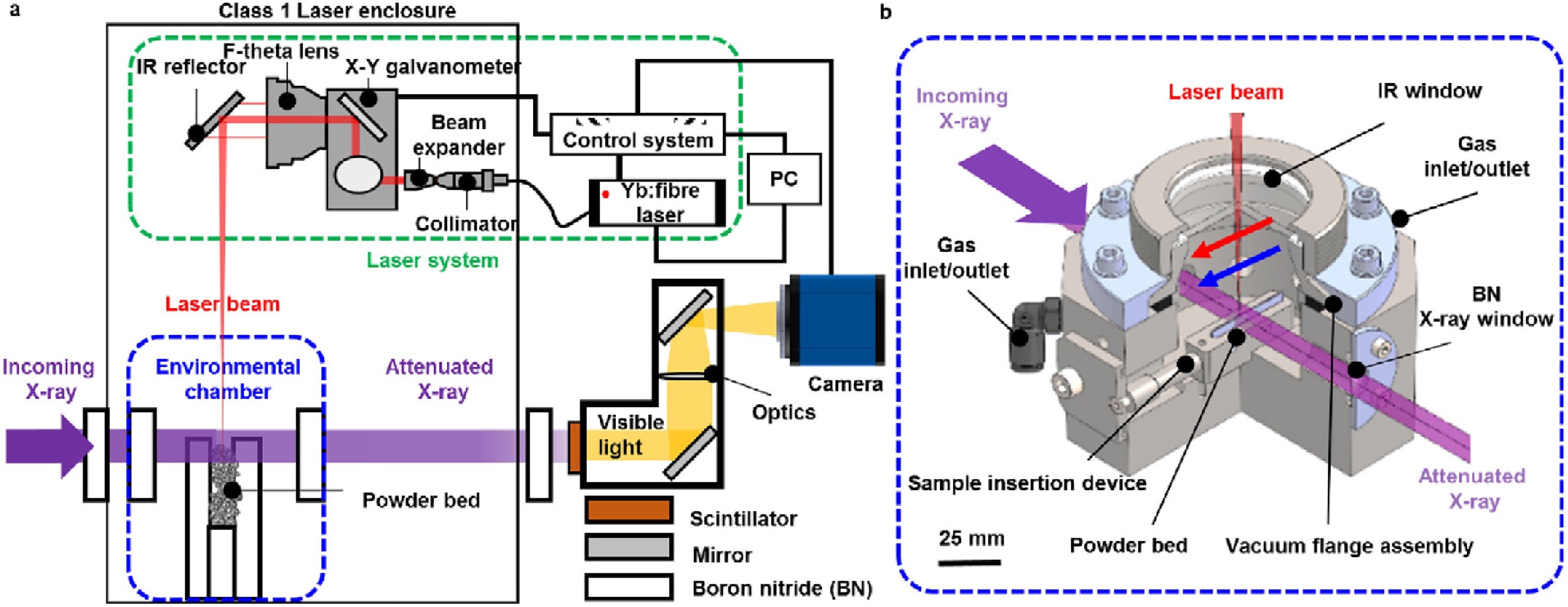

This paper details the use of a custom built LAM process replicator (LAMPR) with in-situ and operando synchrotron X-ray real-time radiography to study laser-matter interactions and powder consolidation phenomena during LAM of stainless steel SS316L and 13-93 bioactive glass.

The paper states the LAMPR is: "Designed to mimic the major features of a typical LPBF system while permitting in situ and operando imaging of the laser-matter interaction and powder consolidation phenomena with synchrotron X-rays. It is a compact, lightweight (ca.15 kg) and portable device that can be integrated into different synchrotron X-ray imaging and diffraction beamlines." (Leung et al. 2018, p649)

Two powders with large differences in chemical, optical and thermophysical properties were chosen for the study. This was to better understand the effects of powder properties on laser absorption mechanisms, melt flow behaviour and the evolution of the melt track and defects.

The study revealed the very different melt behaviours of the two powders during LAM.

The work is useful in understanding the mechanisms behind the formation of defects and other technical challenges.

This understanding will help control technical challenges that can affect the use of LAM technologies for high-performance structural applications.

The paper can be viewed here.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...