All Publications /

Publications:

High temperature strength of an ultra high temperature ceramic produced by additive manufacturing.

03 / 12 / 19

Paper: High temperature strength of an ultra high temperature ceramic produced by additive manufacturing.

Publication: Ceramics International.

Authors: Feilden, E., Glymond, D., Saiz, E., Vandeperre, L.

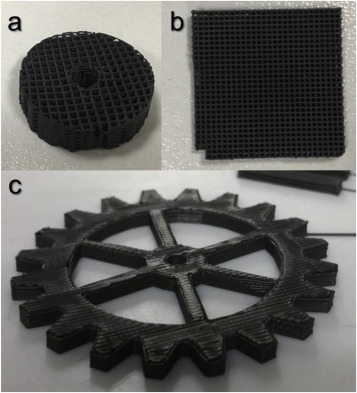

This paper looks at the combination of ultra-high-temperature ceramics (UHTCs) and the additive manufacturing (AM) technique robocasting. UHTCs are a class of heat resistant ceramics that offer excellent stability at temperatures exceeding 2000 °C.

They exhibit a combination of high thermal conductivity and high-temperature strength, making them candidates for thermal protective coatings for applications in space eg. the leading edges of hypersonic and re-entry vehicles.

This research shows that hafnium diboride (HfB2) with good mechanical strength and density can be produced via robocasting. Robocasting is a direct writing AM technique that deposits a continuous flow of paste material through a nozzle in three dimensions. Parts were printed with “complex shapes and internal structures not possible via conventional manufacturing techniques” and the properties – tested up to 1950 °C - were in line with conventionally produced HfB2.

The paper’s authors infer the results could be duplicated with many other UHTC materials, and discuss the advantages over traditional manufacturing methods for both prototyping and complex shape production. Advantages include allowing for complex shapes and internal structures, for example, cooling channels.

Click here to view the paper.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...