All Publications /

Publications:

Graphene Oxide: An All-in-One Processing Additive for 3D Printing.

10 / 01 / 19

PAPER: Graphene Oxide: An All-in-One Processing Additive for 3D Printing.

PUBLICATION: Applied Materials & Interfaces

AUTHORS: García-Tuñón, E., Feilden, E., Zheng, H., D’Elia, E., Leong, A., Saiz, E.

Controlling and tuning rheological behaviour is key for the successful use of 3D printing technologies like robocasting.

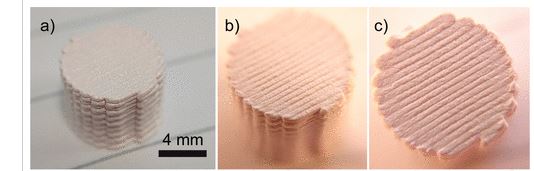

This paper demonstrates how graphene oxide (GO) enables the formulation of water-based pastes to print polymers, ceramics, and steel using robocasting. The GO behaves as a dispersant, viscosifier, and binder.

It states: “This work combines flow and oscillatory rheology to provide further insights into the rheological behaviour of suspensions combining GO with other materials.

“Graphene oxide can be used to manipulate the viscoelastic response, enabling the formulation of pastes with excellent printing behaviour that combine shear thinning flow and a fast recovery of their elastic properties.” (García-Tuñón et al 2017, p32977)

The possibilities for materials manufacturing include the robocasting of complex structures and composites as well as new processing approaches for other traditional and modern techniques such as casting, injection, and roll-to-roll processes.

Click here to view the paper.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...