All Publications /

Publications:

Benefits of adapting processing parameters during SLM builds

13 / 08 / 19

Publication: The International Journal of Advanced Manufacturing Technology

Authors: Ali, H., Ghadbeigi, H., Hosseinzadeh, F., Oliveira, J., Mumtaz, K.

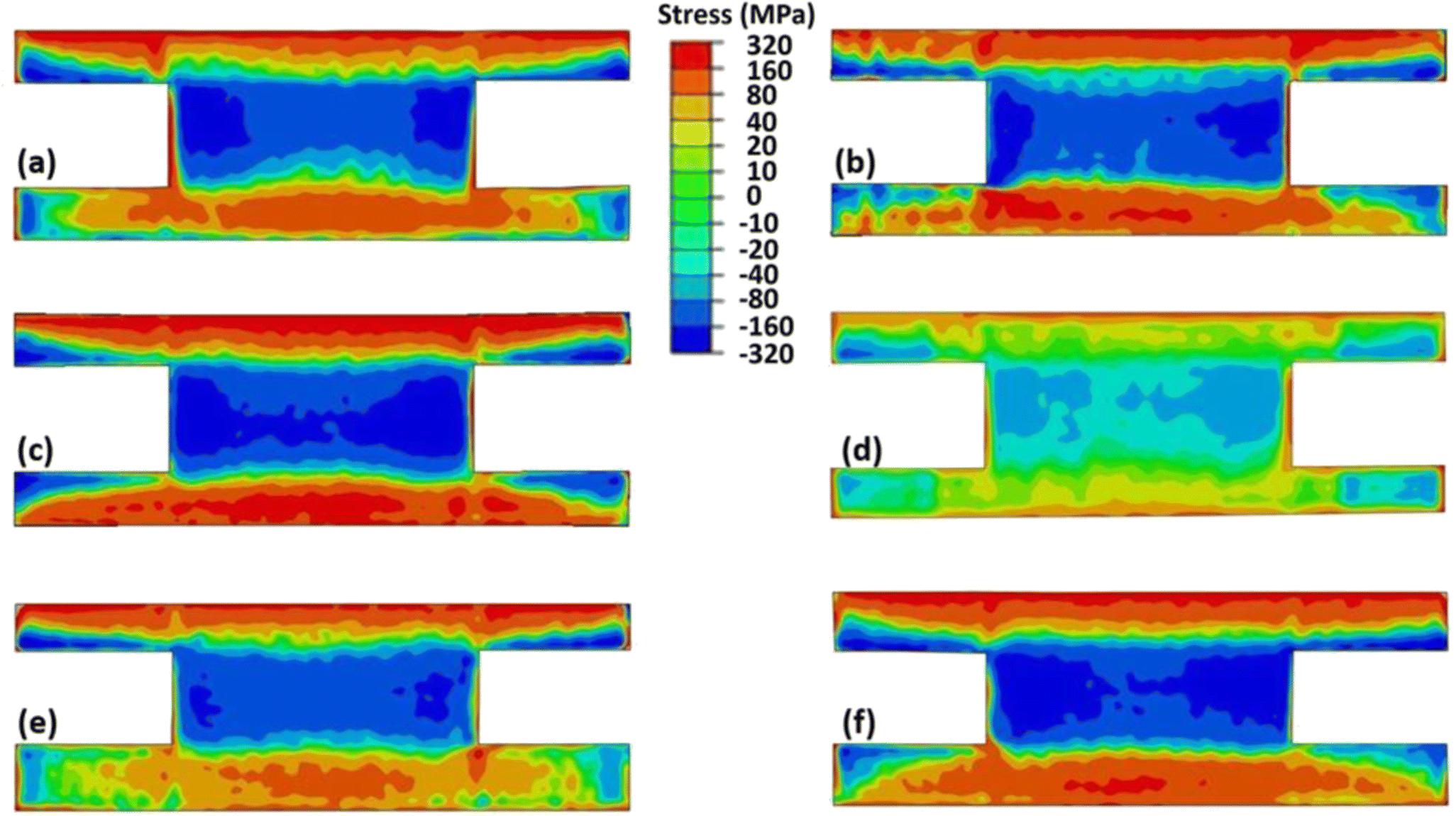

This paper demonstrates the need for selective laser melting (SLM) systems to develop processing parameters that can be adapted during builds.

Being able to react ‘on the fly’ would bring many benefits and help lead to right first time manufacturing.

The paper shows how temporarily switching to an increased layer thickness during the build, below highly stressed regions, redistributed stresses and reduced the overall stresses within the structure.

This temporary switching from standard build parameters to those known to assist in redistributing or reducing stresses would be a key step in developing a more intelligent process.

This intelligent process would reduce build and in-service part failures by anticipating stresses and allowing an action to be taken to remedy them.

The paper states: “The effect of thermally induced residual stresses is not dynamically considered during a selective laser melting (SLM) build; instead, it processes using invariable parameters across the entire component’s cross-section.

“This lack of pre-emptive in-situ parameter adjustment to reduce residual stresses during processing is a lost opportunity for the process with the potential to improve component mechanical properties.

“This work demonstrates the need for current SLM systems to focus on developing a more intelligent processing architecture with parameters that adapt on the fly during a build, in order to manage residual stresses within the built structure.”

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...