All Publications /

Publications:

Diode area melting single-layer parametric analysis of 316L stainless steel powder

01 / 11 / 17

Paper: Diode area melting single-layer parametric analysis of 316L stainless steel powder

Publication: The International Journal of Advanced Manufacturing Technology (2017).

Authors: Miguel Zavala-Arredondo, Kristian M.Groom & Kamran Mumtaz

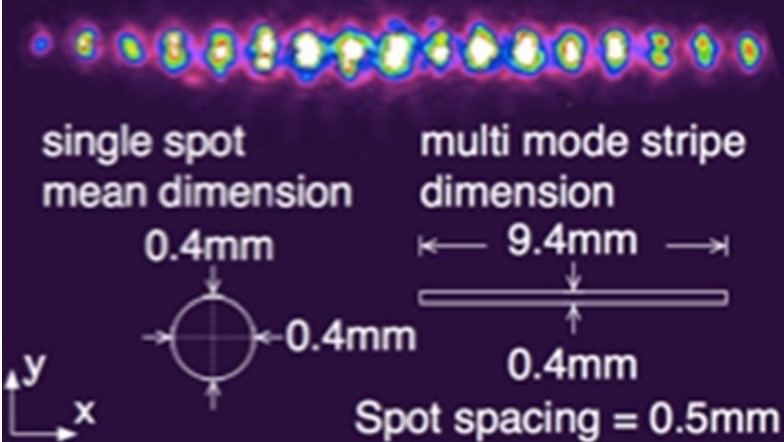

The development of a new AM process - Diode Area Melting (DAM) - a highly scalable approach using energy efficient diode lasers, has opened the door to faster, smaller and cheaper technologies. This is important as one of the challenges to the adoption of AM in high volume sectors such as automotive is overcoming the slow speed of the process.

The paper looks at further understanding the process in regards to the laser energy density required to build parts as quickly as possible. DAM uses a shorter laser wavelength than typical SLM systems allowing for better energy absorption within the powder materials.

The paper presents a parametric analysis of the DAM process and identifies the effect of laser beam profile, laser power, powder characteristics and scan speed on the melt pool, and the conditions needed to produce fully dense metallic components.

The paper can be viewed here.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...