All Publications /

Publications:

A data-driven approach for predicting printability in metal additive manufacturing processes

02 / 12 / 20

Paper: A data-driven approach for predicting printability in metal additive manufacturing processes

Authors: Mycroft, W., Katzman, M., Tammas-Williams, S., Hernandez-Nava, E., Panoutsos, G., Todd, I., and Kadirkamanathan, V.

Publication: Journal of Intelligent Manufacturing

This paper details the first machine learning framework that explores the geometric limits of printability in additive manufacturing (AM) processes before manufacture.

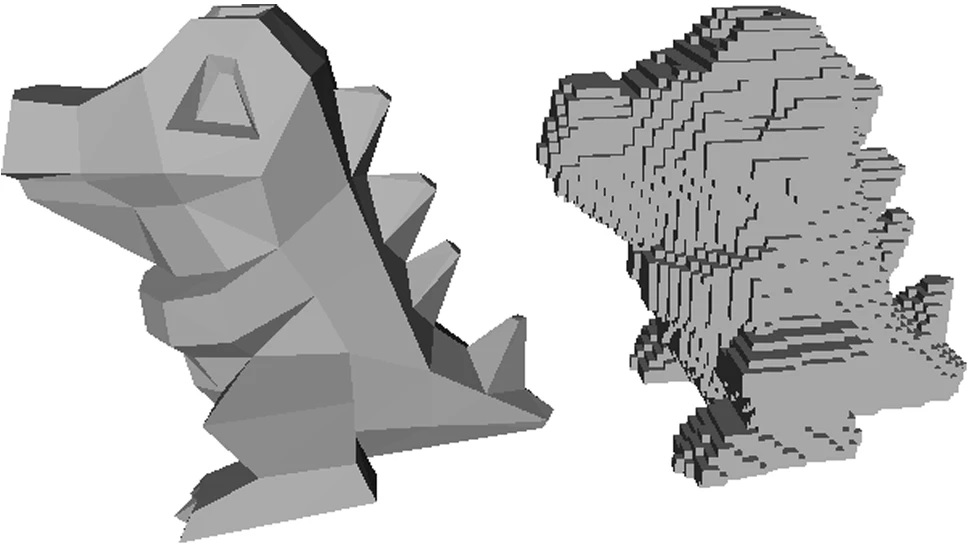

Printability describes the ability of the AM process to produce a faithful realisation of the object.

AM allows for the use of geometries that would be difficult or impossible to produce with other methods.

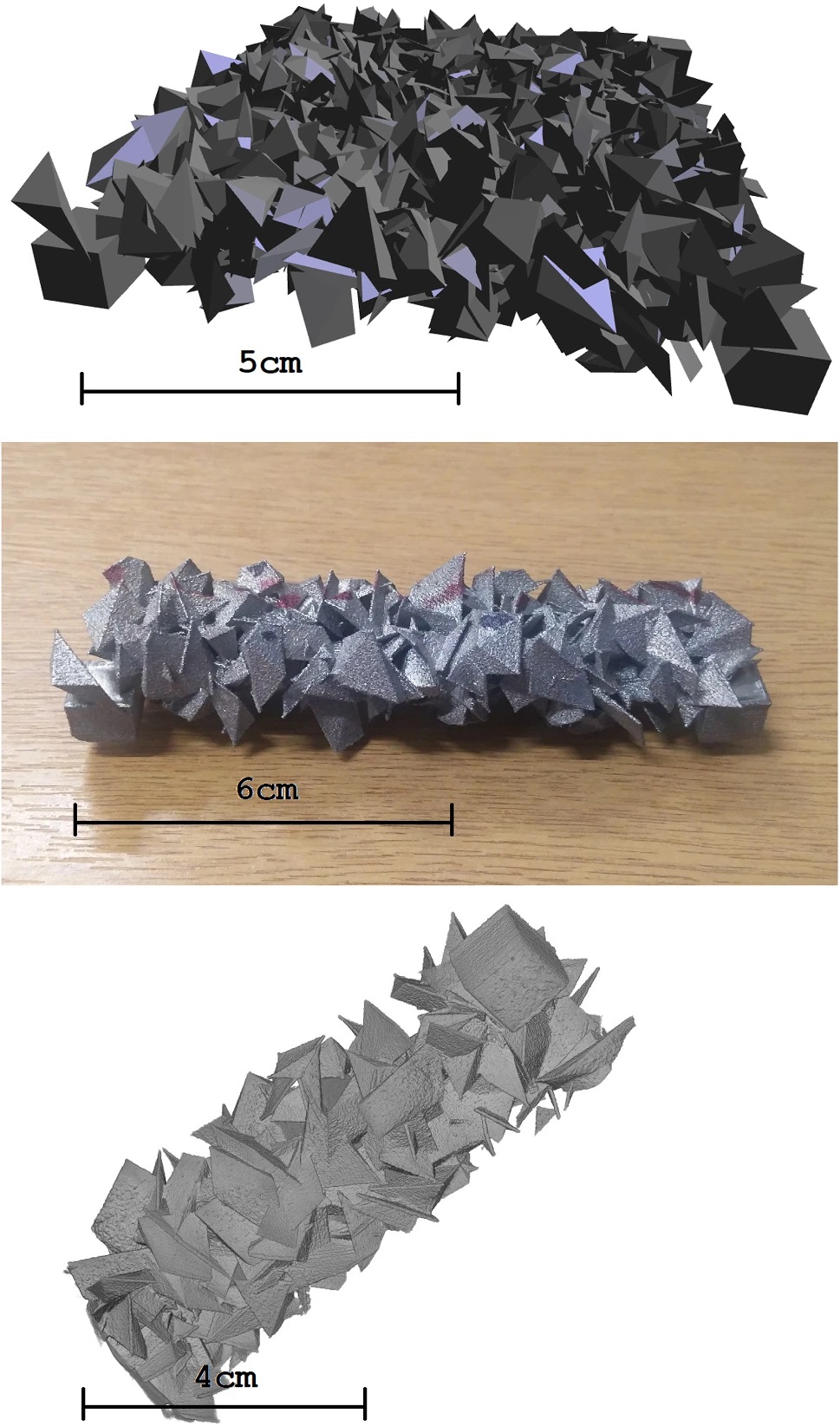

This study focuses on electron beam melting (EBM) which is a form of metal powder bed fusion (PBF) that can build parts at a relatively high speed. Parts are checked for printability and fragility after they are built. Fragility describes its ability to withstand post-printing processing and normal usage.

EBM printability defects can be classified as large-scale deformations caused by stresses on the part during the build process and small-scale defects which describe when small regions are damaged, deformed or fail to print.

Large-scale defects can be predicted using physics based modelling. This paper focuses on small-scale defects.

The paper explains how manufacturers rely on “engineering know-how and ad-hoc rules” and often “err on the side of caution,” to determine which geometric structures are additively manufacturable and the operation conditions required.

It goes on to detail a framework for predicting the printability of small-scale geometric features in AM.

The framework consists of:

- An algorithm for constructing informative test artefacts which can be used to evaluate the geometric limits of AM technologies,

- A method for measuring small-scale printability, even on strenuous components containing large-scale defects,

- Several descriptors of local geometry which correlate with printability and are suitable inputs for many machine learning algorithms,

- “Predictive models which significantly outperform naive benchmarks and approach an estimate of the maximum performance obtainable,” (Mycroft et al 2020).

Click here to view the paper.

Images from the paper published under Creative Commons Attribution 4.0 International License.

More:

Publications

-

-

X1 Case Study B (UCL)

Impact of powder oxidation during additive manufacturing

Investigators: Prof Peter Lee

Researchers: Prof Chu...