All Demonstrators /

Demonstrators:

University College London and University of Manchester insights into Hot Isostatic Pressing

07 / 04 / 22

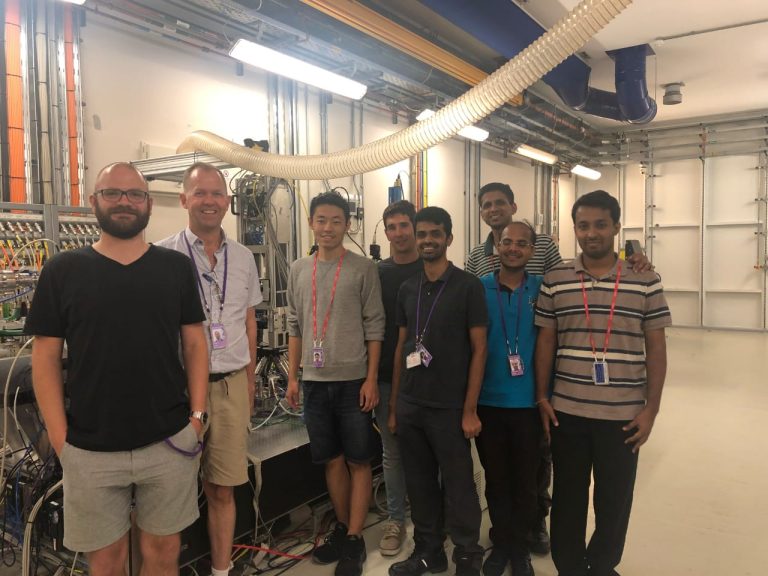

Useful insights have been gained into the Hot Isostatic Pressing (HIPing) process of a novel Ti-Fe binary alloy via in-situ mimic HIPing experiments under synchrotron X-ray at Diamond Light Source, the UK’s national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire.

For the first time, the whole densification process from elementary Ti and Fe powders to a fully dense Ti-Fe composite has been recorded by X-ray imaging.

The consolidation of the powders and the deformation of the powders into each other have been successfully captured.

The outcomes will serve as a good starting point to understanding the effect of powder characters on their HIPing response. Moreover, these results will be a solid reference to validate the processing models against.

In-situ diffusion of the fully-dense Ti-Fe composites has been investigated using synchrotron X-ray. The progressive ‘dissolution’ of the Fe particles into the Ti matrix was recorded.

The outcomes underpin the understanding of the inter-diffusion process that is generally essential during the homogenisation of an alloy produced by HIPing elementary powders.

This coupled with phase composition determined by X-ray diffraction will help tailor the design of alloy composition and microstructure for improved alloy properties.

Informed by the direct observation of the key processes in HIPing, the Manchester team is aiming to develop image-based models to simulate the actual HIPing process. Such models, when calibrated against the experimental observations, will produce a valuable guide on HIPing parameter optimisation and understanding the role of material properties on their HIPing response.

More:

Demonstrators

-

Video/ Animation illustrating Directed Energy Deposition (DED) -

Solid-State Processing of Surplus Aluminium Alloy Powders through a Combination of Field Assisted Sintering Technology and Hot Rolling

The Sheffield Titanium Alloy Research [STAR] group partners with ECKART GmbH to convert surplus aluminium alloy powders from atomisation...

-