Careers / Diode Area Melting - The next generation in multi-laser additive manufacturing of metallic alloys

Developing the next generation in multi-laser based additive manufacturing capability.

EXPIRED

Are you interested in pushing the boundaries of metal additive manufacturing for the creation of components within the aerospace, automotive and medical sectors?

We have an exciting fully funded and well-resourced PhD opportunity available within the EPSRC MAPP Future Manufacturing Hub, developing the next generation in multi-laser based additive manufacturing capability.

Laser powder bed fusion (LPBF) is an additive manufacturing (AM) technique that in recent years has seen a significant increase in industrial usage for the manufacture of high-value end-use components, creating geometrically efficient complex structures with low material wastage.

However, the LPBF processing methodology has not evolved in over two decades, relying on galvo-scanning systems and high power fibre lasers to selectively melt thin layers of feedstock from a powder bed. This approach creates challenges in regard to LPBF system scalability, processing efficiency (due to poor laser absorption and wall-plug efficiency) and thermal process control that is associated with rapid melt-pool solidification, subsequently leading to the creation of components defects (e.g cracking, distortion).

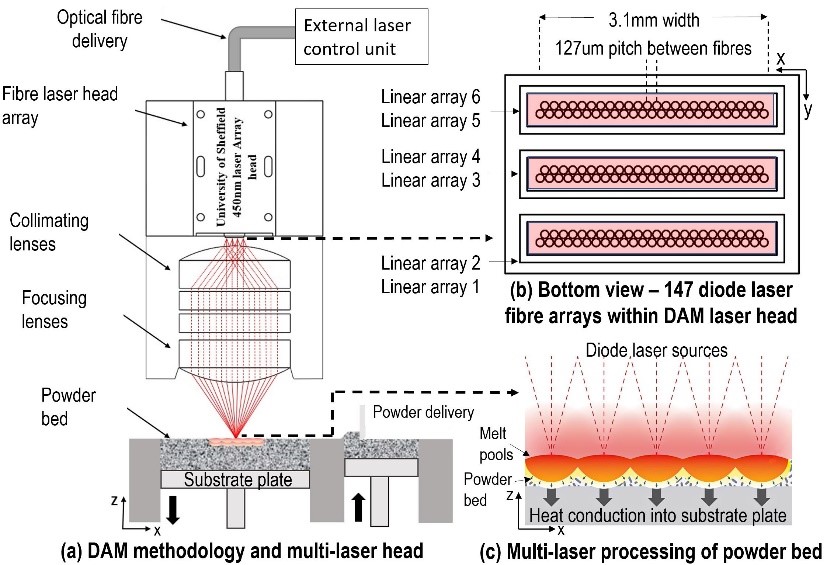

This PhD research will investigate a new multi-laser process invented at the University of Sheffield, known as Diode Area Melting (DAM) illustrated in the figure below. The process uses multiple arrays of efficient low wavelength (450-808nm) and highly focused diode lasers to melt pre-deposited feedstock from a powder bed. This approach offers improved system scalability and thermal control compared to state-of-the-art LPBF. The DAM system to be used during this research will integrate 147 lasers stacked in a unique 2D array enabling advanced in-situ thermal pre/post-heating (see section b in the figure below). The research will focus on developing the system, understanding multi-laser interactions (see section c in the figure below) and the influence on microstructure and mechanical performance of components.

This is a fantastic opportunity to develop new science and knowledge related to this unique system that has the potential to revolutionise the AM industry.

Funding covers home tuition fees and annual maintenance payments of at least the Research Council minimum for eligible UK applicants.

Candidates should have, or expect to obtain, a first-class or 2:1 degree in Engineering, Physics or Science related discipline.

Please send a copy of your covering letter, and CV to Dr Kamran Mumtaz at k.mumtaz@sheffield.ac.uk. Start dates are flexible between July 2022-October 2022.

The deadline for applications is August 31st 2022